Prepress and Postpress- Very Important for Every Graphic Designer

Printing process includes a lot of steps and every step has its own importance. There are a lot of activities even before the printing like Design, Preflighting and after the actual printing is over, like cutting, folding, assembling and binding. But it is not always necessary that all printed items are subjected to these processes. For example, advertising pamphlets does not require binding.

Three important printing processes are:

- PrePress

- Press

- PostPress

What is PrePress?

Prepress is the terminology used to define processes that happens before printing and finishing. Since several publications nowadays are published both in print and electronic media, many shared processes are referred to as premedia services instead.

PrePress Processes

The prepress processes which are mentioned below may take place at single location, like large publishing or printing house, or at different places. Generally, few tasks happen at a publisher end while few take place at a dedicated prepress company (which are also known as service bureaus or trade shops).

- Design: Since the advent of desktop publishing, several people in the printing industry don’t take design to be a prepress task. The design process includes following things

- Preparation of data, which comprises of copyediting and product photography, for example for a mail order catalogue.

- Making the layout is done by using one of the principal computer design application such as Adobe InDesign or QuarkXPress. Sometimes people take usage of tools like Microsoft Office or Publisher. There is also a extensive range of specialized applications are available for tasks like database publishing.

- The rectification sequence contains processes like proofreading and image retouching, for which Adobe Photoshop is the best application available in the market.

- Preflighting: Before finished pages go through the rest of the processes, a validation needs to be done to check if all the data meet the critical production requirements.

- Proofing: During the design phase, page proofs were already being created. Proofs are also done by the company which is responsible for the printing. This is done for internal checks of the impositioning as well as for the customers who need to sign off the proofs for approval. Hardcopy proofing is still very popular in the case of adequate time for it and for color critical or expensive jobs.

- Imposition: Number of pages will be united into signatures as per the final output device.

- To output data, pages or complete flats have to be ripped or rendered. This process also includes:

- transparency flattening: transparency effects like drop shadows behind text need to be fixed.

- screening

- trapping

- managing colors

- color partition

Some people delay the above-mentioned processes to the last moment. This is commonly known as late binding.

Most of the above-mentioned processes are automated nowadays, with the help of either stand-alone applications or prepress workflow systems. The automation process also allows for more intricate communication processes:

- Exchanging data like the final layout can still happen with the help of a DVD. Earlier people used to use the original layout file(s) and all associated images, fonts and other data. Nowadays, instead PDF files are used instead.

- Nowadays use of internet has increased for submitting jobs. This is also known as web-to-print.

- When the data exchange is purely dependent on page content, solutions like FTP server or e-mail or file sharing tools such as DropBox or YouSendIt are used. A more sophisticated web portal can add functions such as preflighting and page approval.

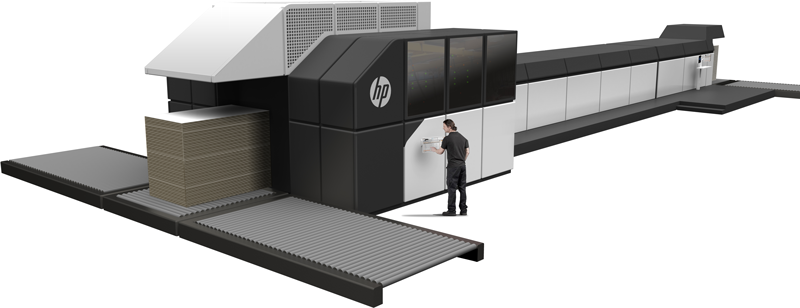

What is Press?

After prepress, the next phase is Press. During printing, accuracy is crucial for both quality and timely delivery, so projects only go to press after they have passed the pre-press and plate making stages, which will result in cutting out any need for costly reprints.

There are several different kinds of printing process and the choice of process depends on the kind of job. Machine printers may specialise in one particular printing process. Most machines are computer controlled. A machine printer's tasks can include:

- preparing the paper or card so that it runs smoothly through the machine

- positioning the printing plates in the press and taking trial prints to ensure everything is correctly placed

- loading the machine with inks and making sure colours are reproduced correctly

- maintaining quality checks during the running of the press

- looking out for problems, such as paper jams, to avoid machine downtime

- routine maintenance and cleaning of the press.

What is PostPress?

PostPress is a crucial part of any printing process and it takes place after the actual printing. It helps in determines the final look, shape and feel of the printed product.

Post press consists of several sub processes that are implemented depending upon the type of the project and the job being handled. Some of the basic types of post press operations in printing industry which are often used are as follows:

- Cutting: This is one of the most common operations of post press which is used in almost all projects. For this purpose, the machines which used are known as “guillotine cutter” or "paper cutter". These are special machines which are used for cutting large substrates of web-type into different sheets or pages. These machines differ in sizes, features, abilities, capacities and configurations; because they are built for individual purposes.

- Folding: This activity is performed mostly in printing workshops for pamphlets, magazines and product boxes. There are mainly three types of folders used in print shops – bone folder, knife folder and buckle folder.

- Bone folder is the one of the oldest among its peers that are made either of bone or plastic. Today they are used occasionally only for high quality jobs.

- Knife folders use knife to force the paper getting into the roller for folding.

- Buckle folder will convert a sheet into buckle so as to pass it between the two rotating rollers.

- Assembling: In assembly, there are three main steps which should be followed - gathering, collating and inserting.

- Gathering is a method of placing bunch of sheets one after another. This is done for assembling books with page thicknesses ranging between 3 to 8 inches.

- Collating is a process of gathering individual sheets of paper instead of bunch of papers. The last step will be inserting involves the process of combining signatures or bunch of papers by “inserting” one into another.

- Inserting is done for the papers with signature pieces having final thickness less than one-half inches.

- Biding: In this category, the printed material or pages are stick together. Three most common binding techniques which are used are- adhesive binding, side binding and saddle binding. For completing binding process, three individual types of covers are used. They are –

- self-covers

- soft-covers

- case-bound covers.

Some of the job profiles in this field are:

- Printing Worker,

- Prepress Technician,

- Press workers and Software designer for print industry.

A digital print press operator uses digital printing machines and software programs to efficiently create materials as per client requirements. In fulfilling these requests, operators may change many variables in the printing press set-up, such as dimension, color or contrast.

The best way to learn these concepts is by joining a professional graphic design institute which can provide training in advanced level concepts of Pre-Press and Post Press. That is why print101naija is there for you. Join us today to start expanding your career.